As an advanced manufacturing method, CNC machining technology is becoming an important means of manufacturing automotive mechanical molds. Through CNC machining technology, automation, precision, and customization of mold manufacturing can be realized. Rapid tooling services improve the quality and efficiency of automobile manufacturing.

Except for some plane or rotating surface parts, automotive molds are mostly complex irregular shapes, which is difficult for traditional processing methods. However, combined with the CNC EDM process and milling process can effectively achieve the diversity of mold manufacturing. And it meets the demand for high-precision machining of automotive molds.

CNC Milling Technology

The application of CNC milling technology is more common in the automotive mold manufacturing industry.

Complex Parts Machining

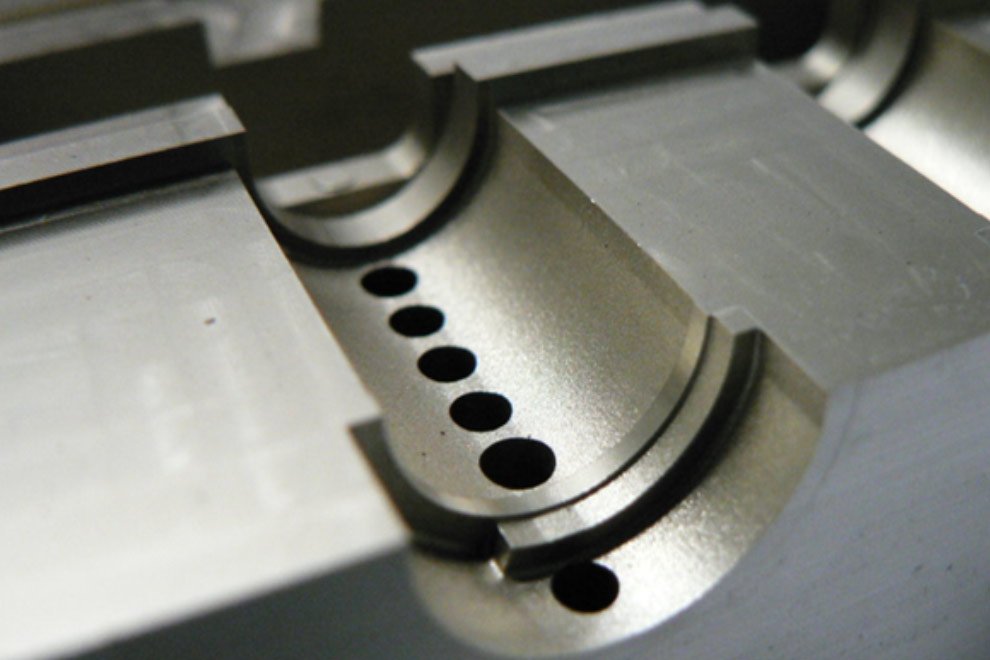

Automotive molds often have complex three-dimensional surfaces and structures. CNC milling technology can meet the demand for high-precision machining of automotive molds through multi-axis movement. For example, in wheel hub processing, the wheel hub usually has complex internal and external contours and holes. CNC milling technology can efficiently process the wheel hub structure under the design through precise tool control, motion path, cutting depth, and so on.

Applicable to the Processing of Various Materials

Commonly used materials for automotive molds include metal, plastic, composite materials, etc. In CNC milling, choosing the appropriate tool and processing parameters is based on the characteristics of different materials. For example, during the automotive crankshaft processing, the machining materials are usually high-strength alloy steel. By adjusting the cutting speed, feed rate, and other parameters, CNC milling can process crankshafts in different materials. Through precise processing of crank pins, journals, and other parts, the balance and stability of the crankshaft are ensured.

For some automotive molds requiring more complex and special manufacturing processes, you also need to use the computer and CAD software and so on. Technicians need to strictly control the speed range of the machine spindle. Also, the processing necessitates standardizing the operation of the CNC drive system and checking the system parameters, to ensure the stable and reliable operation of the milling machine.

CNC Turning Technology

In automotive mold manufacturing, turning processing is an important step. The specific operation process involves many parameters, such as feed rate and spindle speed. Different parameters result in varying CNC instructions.

Besides, CNC turning technology is helpful for the processing of different shapes of automotive molds, such as rotating bodies and rods. Rotating body mold processing mainly includes shafts, bowl-shaped models, injection solid models, and bottle models. The flat production processing of molds is generally easier to operate.

Therefore, CNC turning technology is generally used for processing automotive mold of some dispersed parts. Then by the actual demand, the production of overall mold starts with other technologies as aids.

EDM Technology

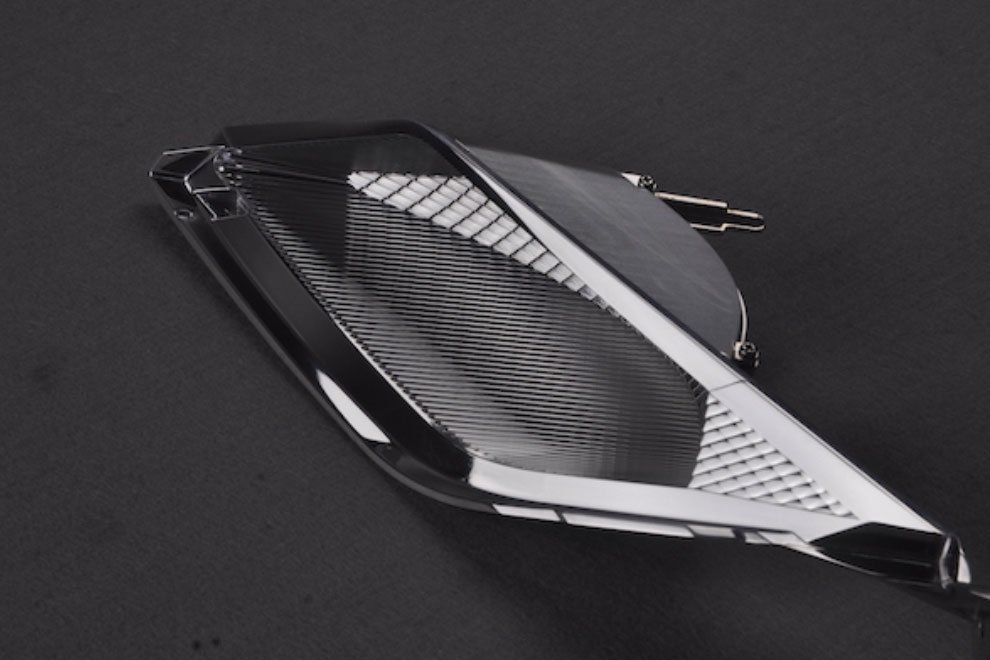

Using EDM for automotive mold processing can meet the demand for rapid prototyping of molds. The actual processing process involves machining small holes with high-speed EDM, forming and wire cutting, and so on. Each technology has different processing requirements, with its advantages and disadvantages.

In rapid tooling services, the wire-EDM is usually applied for straight-walled molds. For example, make concave and convex molds in the production of stamping molds, or apply electrodes in the CNC EDM technology. In automotive mold processing, according to the electrode operation techniques, using CNC EDM technology can get better technical effects. It ensures the straightness and flatness of the processing.

In addition, when applying EDM technology in automotive mold manufacturing, it is necessary to ensure the opposite electrodes between parts and machining tools. The working fluid should be used in the machining process between the electrodes. It plays a certain insulating role to ensure the continuity of the discharge operation in the EDM process.

Expanding the scope of application of CNC EDM technology can further enhance the processing capabilities of automotive molds, thus further improving the accuracy of automotive molds.

Tooling Requirements for Automotive Mold Processing

From the tool holder runs out, high demands are put on the processing of automotive cover parts, and grinding operations are also required after the first processing.

To save processing time, the radial run out of the tool should be controlled as much as possible in terms of tool selection. It reduces tool loss and shortens processing time based on ensuring processing quality.

In terms of automotive mold finishing, the staff needs to reasonably control the dynamic balance value of the tool. For automotive cover parts mold finishing, the requirements of tool dynamic balance control are more stringent because of its complex surface processing technology. If the machine speed is 8,000 r/min, the dynamic balance of the tool should be controlled at about 0.004 mm.

In terms of hardened machining, it is necessary to use quenching technology and a ball milling cutter to process the automotive column, as well as front and rear longitudinal beam molds.

In addition, because the cutting fluid has the function of cooling the tool, the solid carbide tools should be applied when the cutting fluid isn’t used. In the process of processing, it can take away the heat with the help of iron filings, to ensure the quality of mold processing.

Conclusion

Due to the high requirements of rapid tooling services, it is essential to enhance production capacity while maintaining mold quality through the application of CNC machining technology.

Given the diverse methods of automotive mold production, technicians must first understand the specific manufacturing requirements of each mold. They then need to select the appropriate CNC machining techniques and ensure their proper application throughout the manufacturing process.

This approach not only improves the quality of the molds but also minimizes the need for rework, thereby reducing economic losses for the company. For molds with personalized manufacturing requirements, technicians can refine and optimize CNC machining processes to ensure flexible and effective use of the technology.